Today’s industrial systems are no longer isolated solutions, they operate in a realm where many machines and components on a shop floor as well as all over the world are connected as part of a large production network. This poses a number of challenges for machine manufacturers and plant operators, one of them being the precise synchronization of devices within such distributed systems.

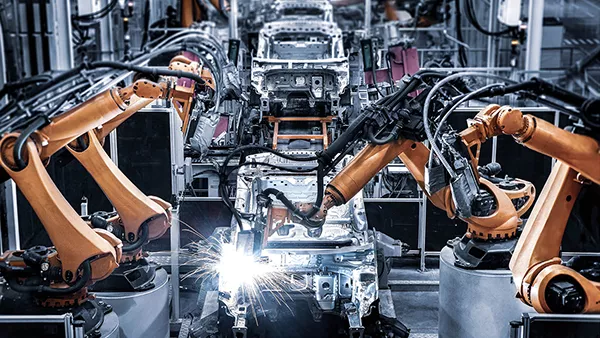

The Precision Time Protocol (PTP) helps to ensure accurate timing throughout the network. Why is clock synchronization important? Picture an automotive factory with a long line of assembly robots, each of which is responsible for adding a specific part to the car as it is manufactured. In an assembly line, the product is moved forward in exactly timed increments along the line and the placement of the parts may be dependent on each other (e.g. the window can only be inserted once a doorframe has been added). This is where PTP helps ensure that the timing of the robots is synchronized, so that they can seamlessly operate with each other. However, other industries also make use of PTP for monitoring and protocolling their processes and in the evaluation and analysis of data and systems in order to increase the efficiency of their equipment and or predictions.

We sat down with Steffen Schmidt-Evers, Senior Key Account Manager Deterministic Ethernet, TTTech Industrial to find out more about the PTP and its use cases.

What is the PTP and how does it work?

The PTP is an IEEE/IEC standardized protocol used for highly accurate distribution of time across packet networks. PTP defines the exchange of messages between the nodes of a packet network that enable the synchronization of the network’s clocks. Put in highly simplified terms, PTP works by sending a message from a master clock (i.e. the most accurate clock in the network) to all other clocks (the “slave clocks”) that tells the slave clocks what time it is at the master clock, so the slave clocks can adjust their time to that of the master clock.

What is the difference between PTP and the Network Time Protocol (NTP)?

The main difference is in the accuracy that can be achieved and the use case. While NTP solutions are used in WAN application and achieve millisecond-level synchronization, PTP networks are used in LAN applications and aim to achieve nanosecond- or even picosecond-level synchronization. The accuracy of NTP is good enough for many commercial and industrial network applications. However, for applications requiring higher levels of accuracy, PTP is the right choice.

Can you name an example for applications that require high accuracy and thus use PTP?

PTP is used in many industries, for example manufacturing, telecommunications, and the energy sector. Examples of manufacturing use cases are the automotive industry, where PTP enables precise synchronization of robots in assembly lines and the printing industry where it ensures exact color distribution. In telecommunications, specialized PTP profiles (ITU-T profiles) are utilized for accurate synchronization of frequencies and phases over packet-like 2G/3G/4G base stations as well as LTE networks. The energy sector also needs precise and reliable controlling to ensure safety and seamless operation in power generation, electricity distribution and smart grid networks. In these applications, PTP is used with its standard or several special power profiles (for example the Power Utility Profile IEC/IEEE 61850-9-3). PTP is also used more and more frequently in professional audio and video equipment to increase transmission accuracy.

Can you tell us more about TTTech Industrial’s expertise in this field?

TTTech Industrial operates under the umbrella of TTTech Group, a leading provider of safe networked computing platforms. It is a leading expert in HSR/PRP and TSN technology. HSR/PRP (High-availability Seamless Redundancy / Parallel Redundancy Protocol) are network protocols for Ethernet that provide seamless failover[1] against failure of any single network component. TSN (Time Sensitive Networking) is an extension of IEEE Ethernet with the goal to provide deterministic connectivity[2] through IEEE 802 networks, i.e. guaranteed packet transport with bounded latency, low packet delay variation, and low packet loss. Both technologies use PTP for the precise time synchronization of all nodes within a network. For this reason, TTTech Industrial developed its own PTP technology inhouse and has been using it in customer projects for more than 10 years.

Please introduce TTTech Industrial’s PTP offering.

TTTech Industrial provides its PTP stack as part of the software package for its HSR/PRP and TSN solutions. This PTP stack is provided as binary software, optimized, tested, and verified for the corresponding TSN and HSR/PRP reference setups. Customers who want to use this stack in systems beyond the offered IP, TTTech Industrial offers the PTP stack as source code product with a one-time license model and optional maintenance.

[1] In case a network component fails, the system automatically switches to a second “standby” component to ensure seamless – i.e. continued – operation.

[2] Deterministic connectivity of network components ensures that messages are sent and received reliably at scheduled/pre-defined times.

Further reading

- Find out more about the technical implementation of PTP in TTTech Industrial’s Edge PTP stack in our whitepaper.

- Edge PTP – product page

- IEEE – PTP standard

- Introduction to Time-Sensitive Networking (TSN)

- Introduction to HSR/PRP