Discover our most common Nerve use cases

What is remote service?

All service and maintenance work that is carried out on machines and production lines without the service technician being on site.

What is

the challenge?

-

Difficult to plan costs and duration of maintenance, especially at remote customer locations

-

Software updates are time consuming, insecure and difficult to track

What are

the benefits?

-

Detect and resolve common errors remotely

-

Consolidate engineering expertise and avoid excessive travel costs

-

Simultaneously deploy software updates to installed machines via secure cloud connection

-

Remotely diagnose and patch software issues

Remote access

with Nerve:

-

Remotely access your devices in your network using an integrated tunnel

-

Directly display a remote desktop of your applications in a browser without the need for installing additional software

-

Collect logs centrally for all your applications and devices

-

Keep your edge software and applications up-to-date

What is condition monitoring?

Condition monitoring keeps track of key indicators for machine performance (vibration, temperature etc.) in order to identify any changes which may be indicative of a developing fault.

What is

the challenge?

- Detect machine's performance changes before a failure occurs

- Errors are often sporadic and difficult to track

- Retrospectively identify the root cause of failure to prevent them

What are

the benefits?

- Ensure maintenance visits are always on time and scheduling is optimal

- Increased machine availability through monitoring of key indicators and early fault detection

- Better and earlier error detection through trend data and data history

Condition monitoring

with Nerve:

- Read sensor data via fieldbuses (PROFINET, EtherCAT) using the real-time Soft PLC module

- Read data from PLCs or other sources (S7, Modbus, OPC UA) using the integrated Data Gateway and store it in a local database

- Visualize the data in local or cloud-based dashboards and create alarms using rules

What is machine learning?

Machine learning algorithms build a model based on sample data, known as training data, in order to make predictions or decisions without being explicitly programmed to do so.

What is

the challenge?

- Interrelationships of functional or behavioral changes in the machines are not recognized

- Model calculation only takes place in the cloud, but execution of the model must take place on the machine in a time-critical manner

What are

the benefits?

- Data ownership and control, whether on-site or in the cloud

- Identification of and response to trends and patterns in machine behaviour

- Error reduction through optimization of processes and improved solution finding

Machine learning

with Nerve:

- Use Nerve Data Services to collect live and training data

- Create and train your models using your preferred machine learning toolkit

- Deploy models and configurations and integrate them into a DevOps flow using the API

- Connect your trained models to live data using applications running on Nerve

- Visualize results in local or cloud-based dashboards

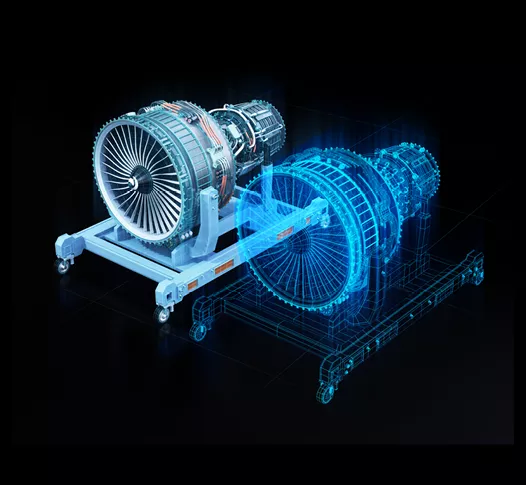

What is a digital twin?

A digital twin is a representation of a physical object, process or service. The twin can be a digital replica of an object in the physical world such as a CNC mill or a turbine. Nerve provides secure access to machine data which acts as the foundation for a digital twin.

What is

the challenge?

- Monitoring the behavior of machines and their interactions is only possible in the real world

- Innovation cycles and improvements need time and a physical setup for evaluation

What are

the benefits?

- Improved test and functional check on a digital twin

- Comparability of behaviors of machines operating in different locations

Digital Twin

with Nerve:

- Securely collect data from the machine and model them in OPC UA for digital twin

- Read sensors using fieldbuses (Profinet, EtherCAT) using the integrated Soft PLC

- Use the integrated data services gateway to upload relevant data for the Digital Twin representation to cloud providers